Concept Basics of Extruded Heatsinks for PCBs

With the raising need for powerful electronic devices and the mission for miniaturization, Printed Circuit Boards (PCBs) have actually ended up being extra advanced in the recent past. Because of heat sink tube , the demand for effective warmth monitoring has additionally enhanced. An extruded heatsink is an essential part and a popular option for managing the warm created by PCBs. In this blog site, we will explore the style basics of extruded heatsinks for PCBs by diving into their value, stabilizing weight and performance, the science behind thermal resistance, anodization methods, and modification capacities.

1. Checking out the Importance of Heatsink Design in PCB Applications

The main factor for using heatsinks in PCBs is to avoid thermal closure, which can occur when the temperature of certain components of a PCB exceeds their operating restrictions. Without a heatsink, PCB components will ultimately fall short, which can bring about catastrophic consequences. A heatsink, on the various other hand, dissipates heat from a PCB with a combination of convective and conductive mechanisms, alleviating the risk of getting too hot.

2. Stabilizing Weight and Performance in Heatsink Selection

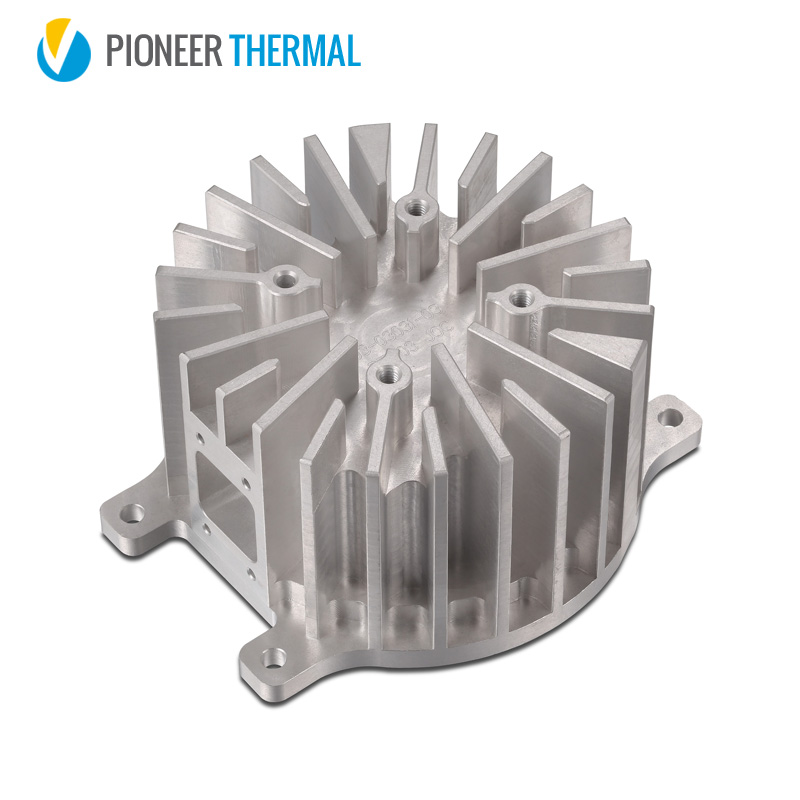

When choosing a heatsink for PCB applications are its weight and efficiency, the two most vital aspects to think about. Extreme weight can produce concerns with transportability and packaging, while insufficient performance can bring about thermal closure. This complicated equilibrium is why extruded heatsinks are one of the most extensively used kind of heatsink for PCBs. Their light-weight yet durable design boosts both thermal efficiency and portability.

3. The Science Behind Thermal Resistance in Extruded Heatsinks

Thermal resistance is among the vital factors that determine the effectiveness of extruded heatsinks in PCB applications. Thermal resistance describes the resistance of a material to the flow of warmth. The style of an extruded heatsink need to focus on lessening thermal resistance. Some vital facets to think about consist of product choice, surface, and fin spacing. Heatsinks made from high-conductivity products, such as aluminum or copper, have low thermal resistance, while raised area and fin spacing enhance air flow and lower thermal resistance.

4. Anodization Techniques: Enhancing Heatsink Durability and Efficiency

Anodizing is an electrochemical procedure by which the surface of a product is coated with a protective layer of oxide. Anodizing enhances the durability and performance of extruded heatsinks by enhancing their rust resistance, scratch resistance, and thermal emissivity. Furthermore, anodizing can improve the heatsink's appearances, making it a lot more appealing to the end-user.

5. Personalization Capabilities: Adapting Heatsinks for Diverse PCBs

Among one of the most substantial benefits of extruded heatsinks is their personalization capabilities. A wide range of customization alternatives enables engineers to adjust the extruded heatsinks to various PCB dimensions, shapes, and efficiency requirements. Some personalization alternatives include surface treatment, post-machining, and sticky capacities. This versatility permits the effective administration of warmth in varied PCB applications.

Effective heat monitoring in PCBs is of utmost relevance, and extruded heatsinks play a substantial duty in making sure the long life and reliability of PCB applications. To attain the most effective warm monitoring, the style of the extruded heatsink should be very carefully considered, thinking about its weight, thermal resistance, and personalization abilities. Anodizing strategies can improve the sturdiness and effectiveness of extruded heatsinks, resulting in longer-lasting and high-performance PCB applications. For all your extruded heatsink requirements, contact us at Renxin -Precision. We provide tailor-made light weight aluminum heatsink remedies, developed to meet your special demands. Contact us today at Tel: +86( 769) 8182 2159 or E-mail: [email protected].

An extruded heatsink is a necessary part and a prominent remedy for handling the heat produced by PCBs. In this blog site, we will check out the design basics of extruded heatsinks for PCBs by diving right into their value, balancing weight and efficiency, the scientific research behind thermal resistance, anodization strategies, and customization capacities.

The main reason for the use of heatsinks in PCBs is to avoid thermal shutdown, which can happen when the temperature of certain elements of a PCB surpasses their operating limits. Thermal resistance is one of the important aspects that figure out the effectiveness of extruded heatsinks in PCB applications. Effective warmth management in PCBs is of utmost significance, and extruded heatsinks play a considerable duty in ensuring the long life and dependability of PCB applications.